There has been a bit of a delay since Part 1 and Part 2 due to Sue having a fall and breaking her arm in three places. This required over three hours of surgery to install enough metalwork and screws to keep a blacksmith happy followed up by a lot of trips back and forth to the hospital. However, on with the install of the Sterling Power Wildside unit. I think that this will be the first ever install of a unit in a caravan.

I printed out copies of the wiring diagrams and loaded up the Amarok with everything I’d need and set off for the storage site. Arriving at the caravan everything was cleared out to give me some space to work.

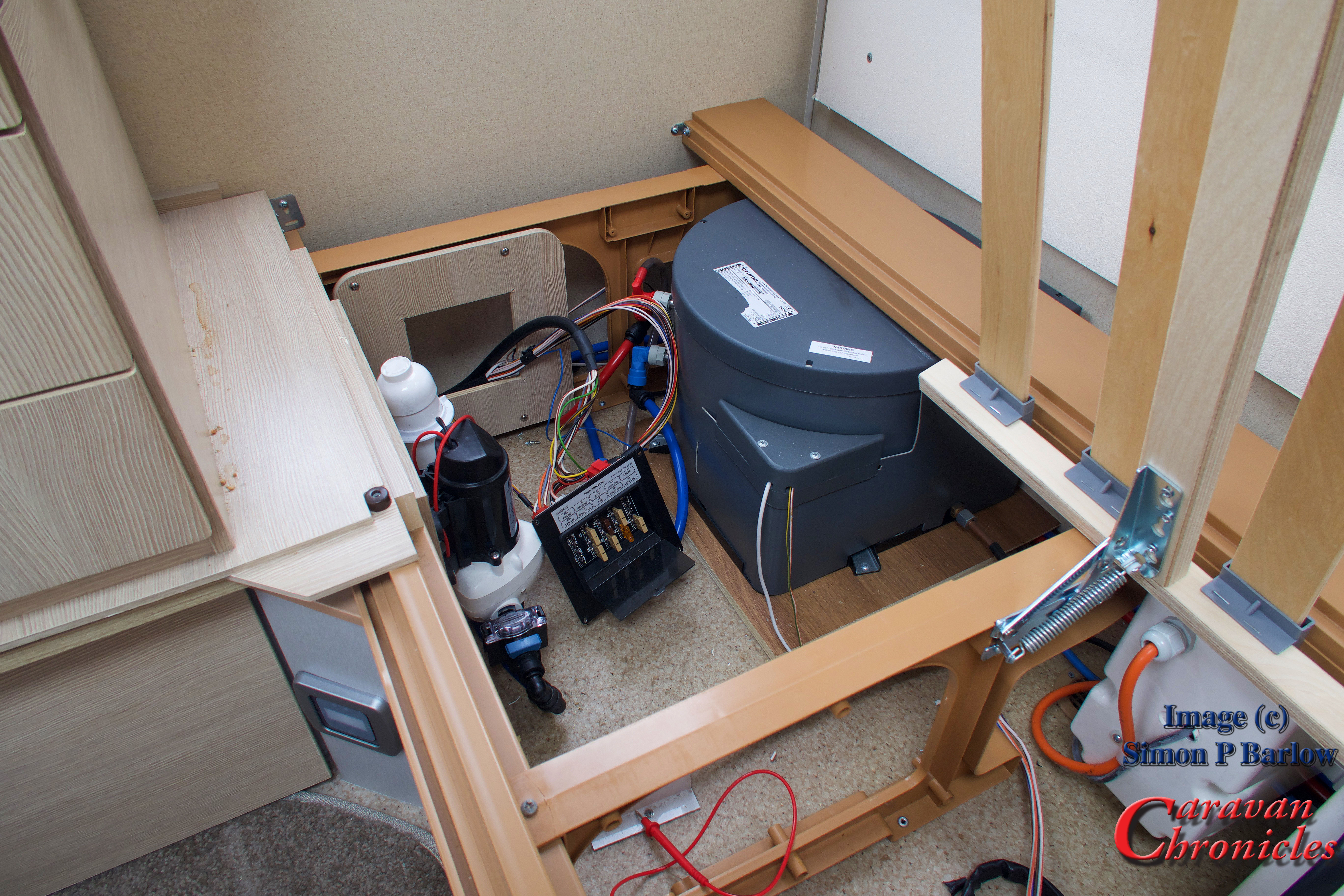

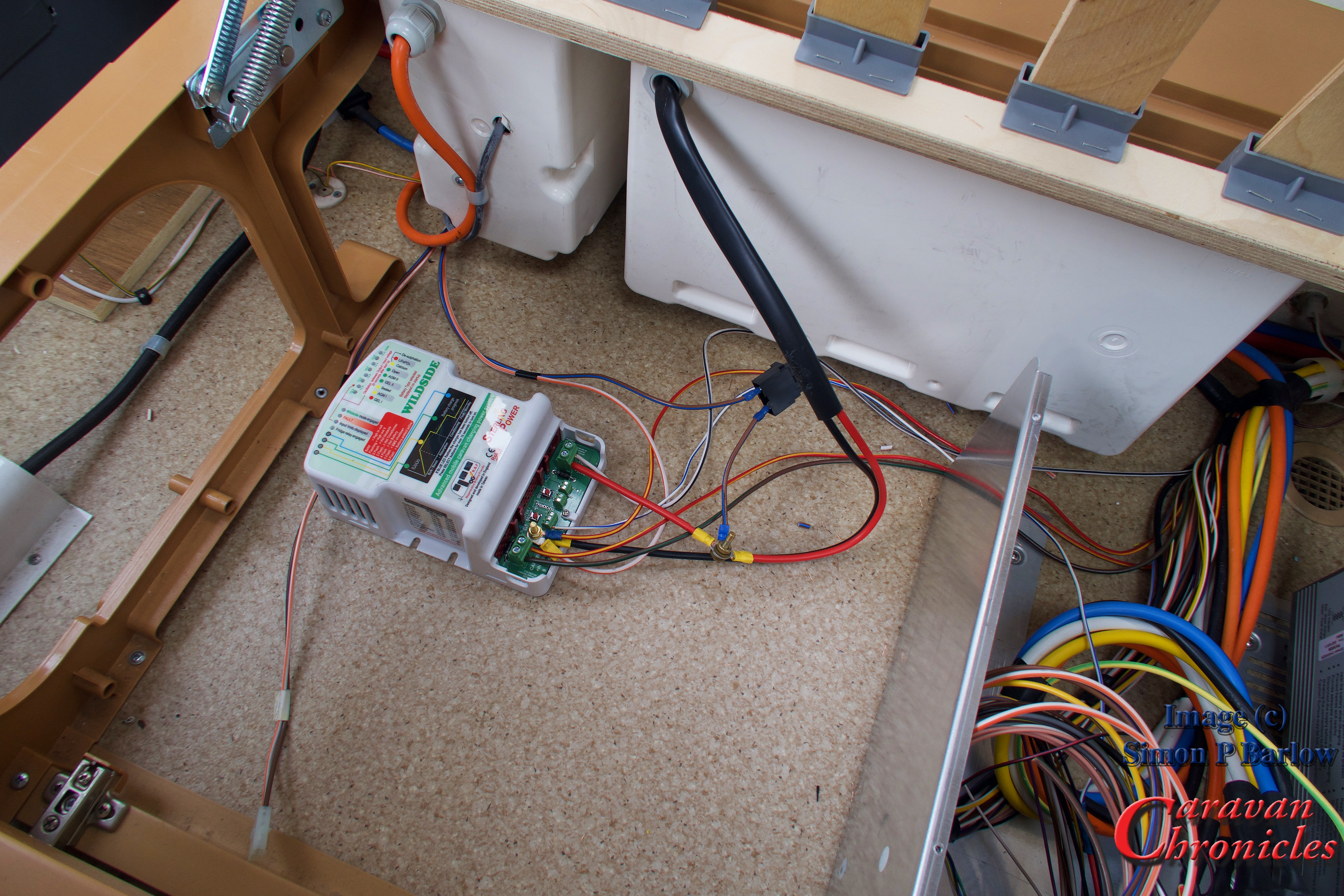

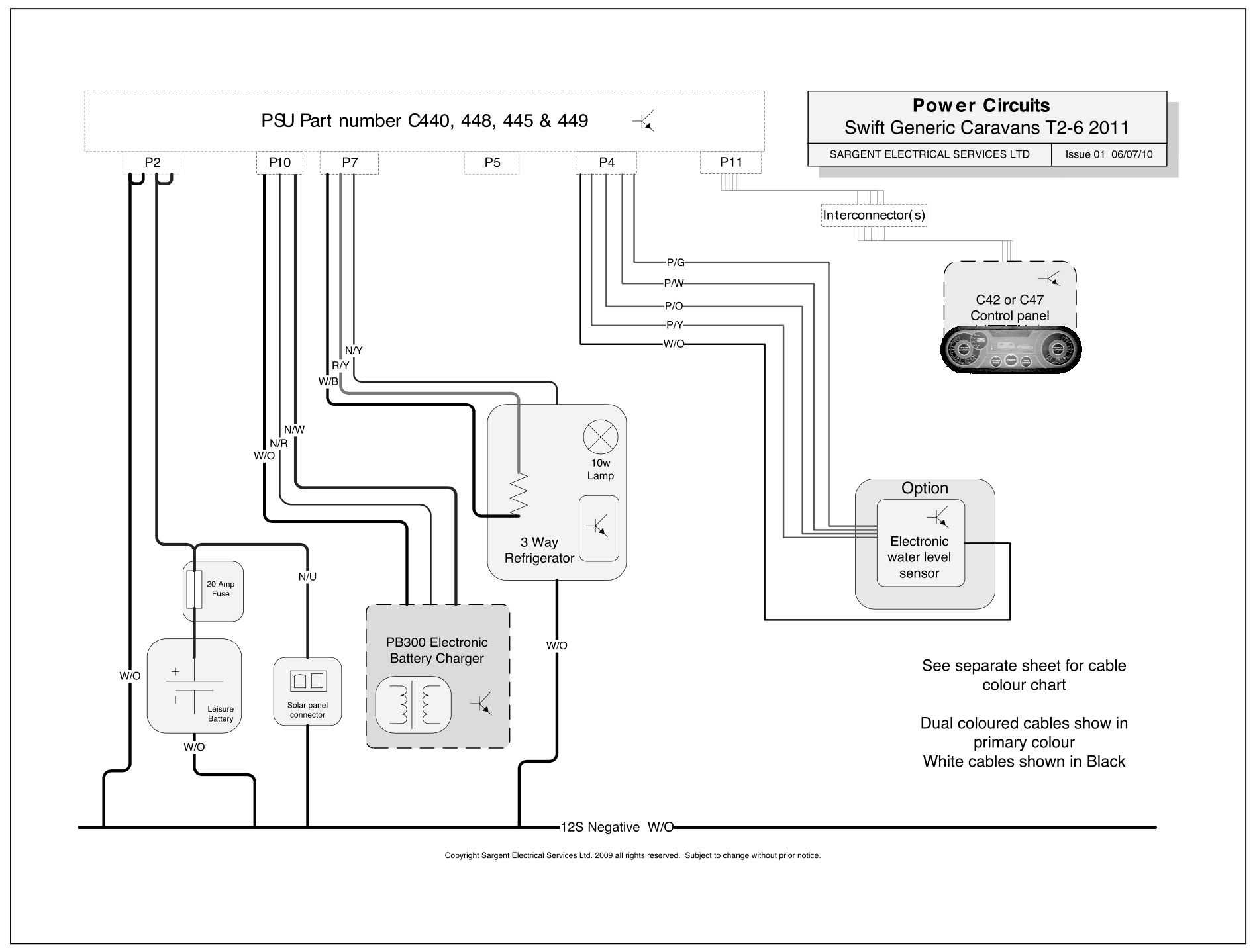

I’d planned to install the unit somewhere close to the Sargent control box as all the connections I’d need could be found here and it was close to the fuse box that connected the lead from the 13 pin plug to the caravan services.

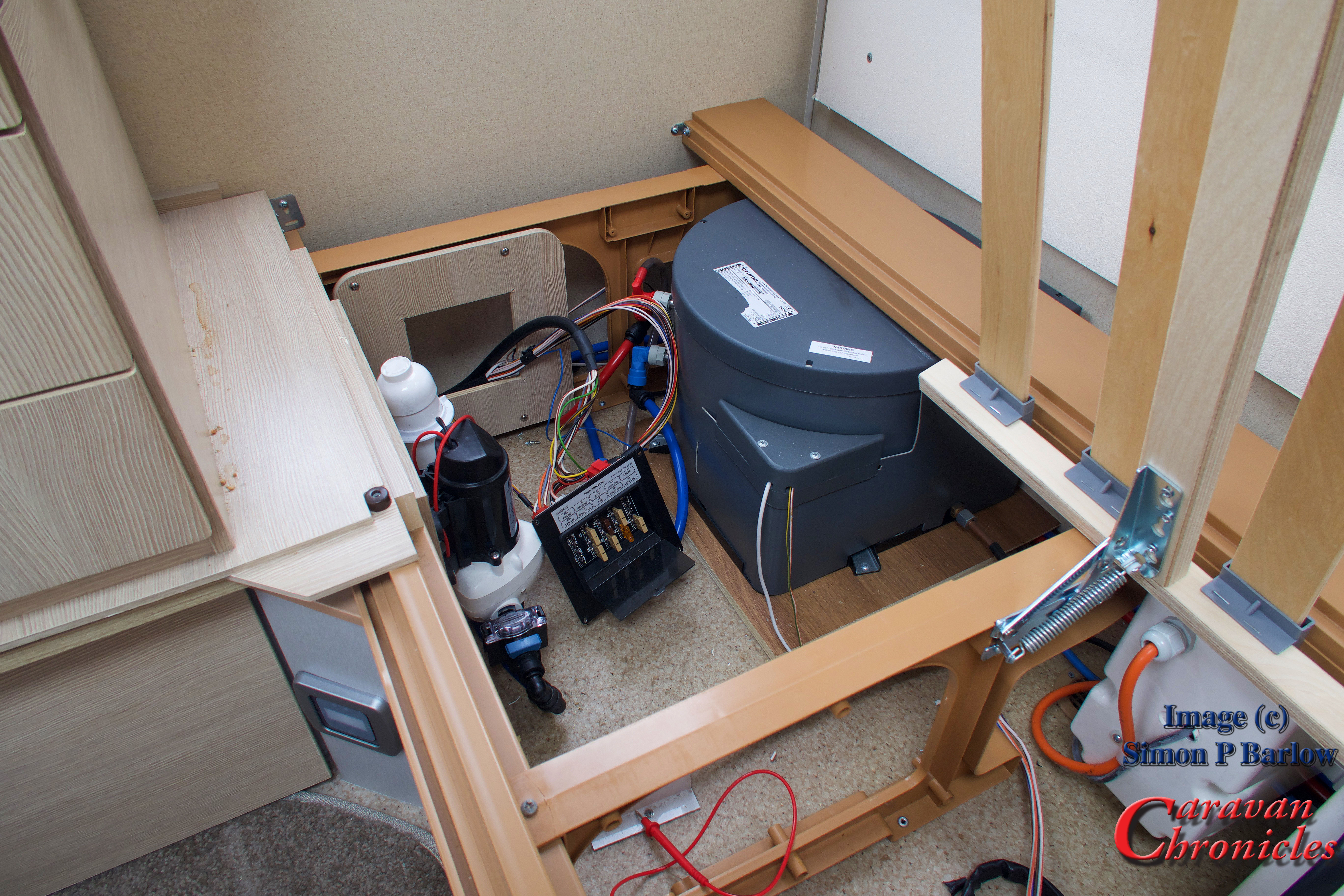

The fuse connection point for the lead from the 13 pin plug is in our caravan, located right at the front next to the centre chest of draws against the gas locker wall.

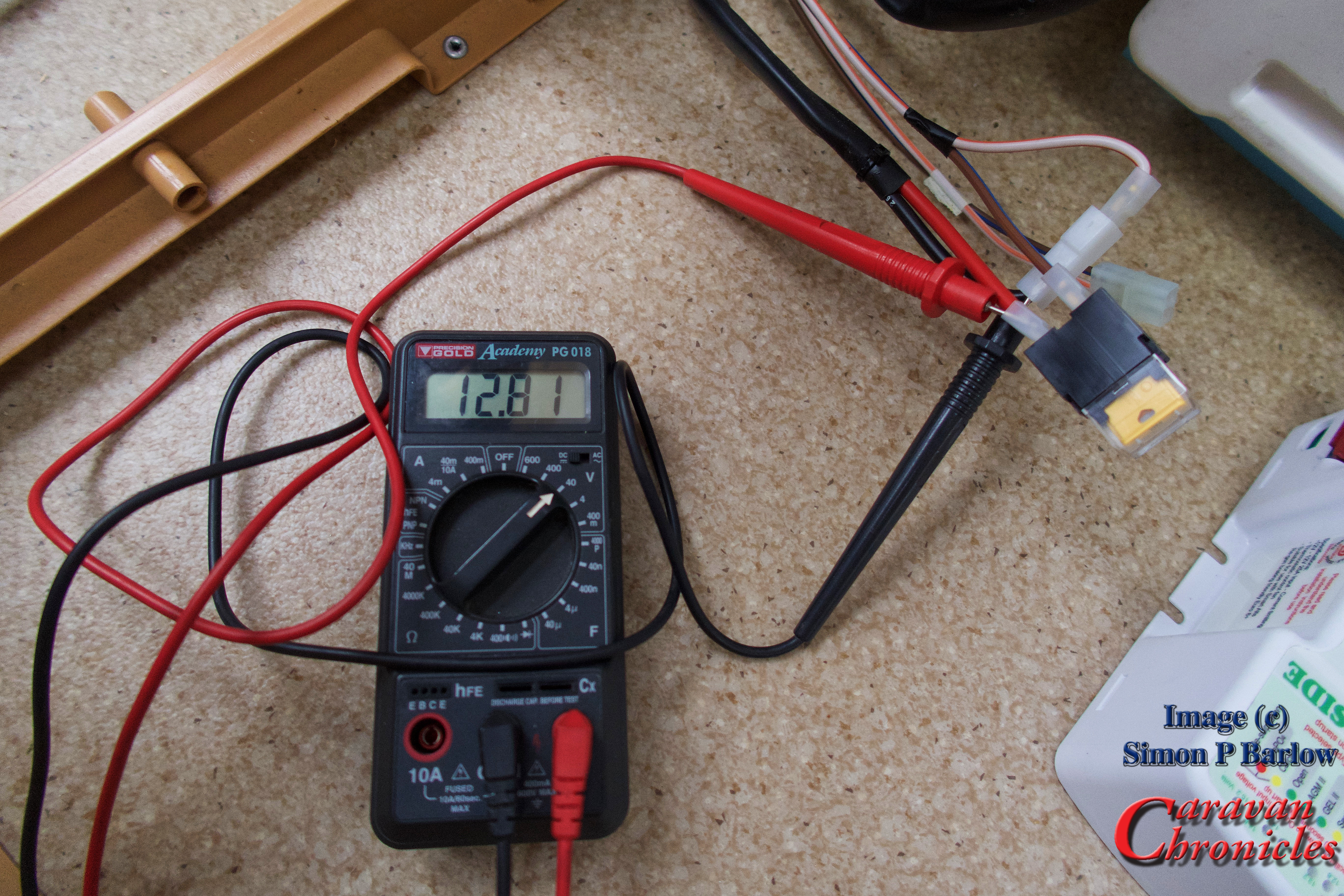

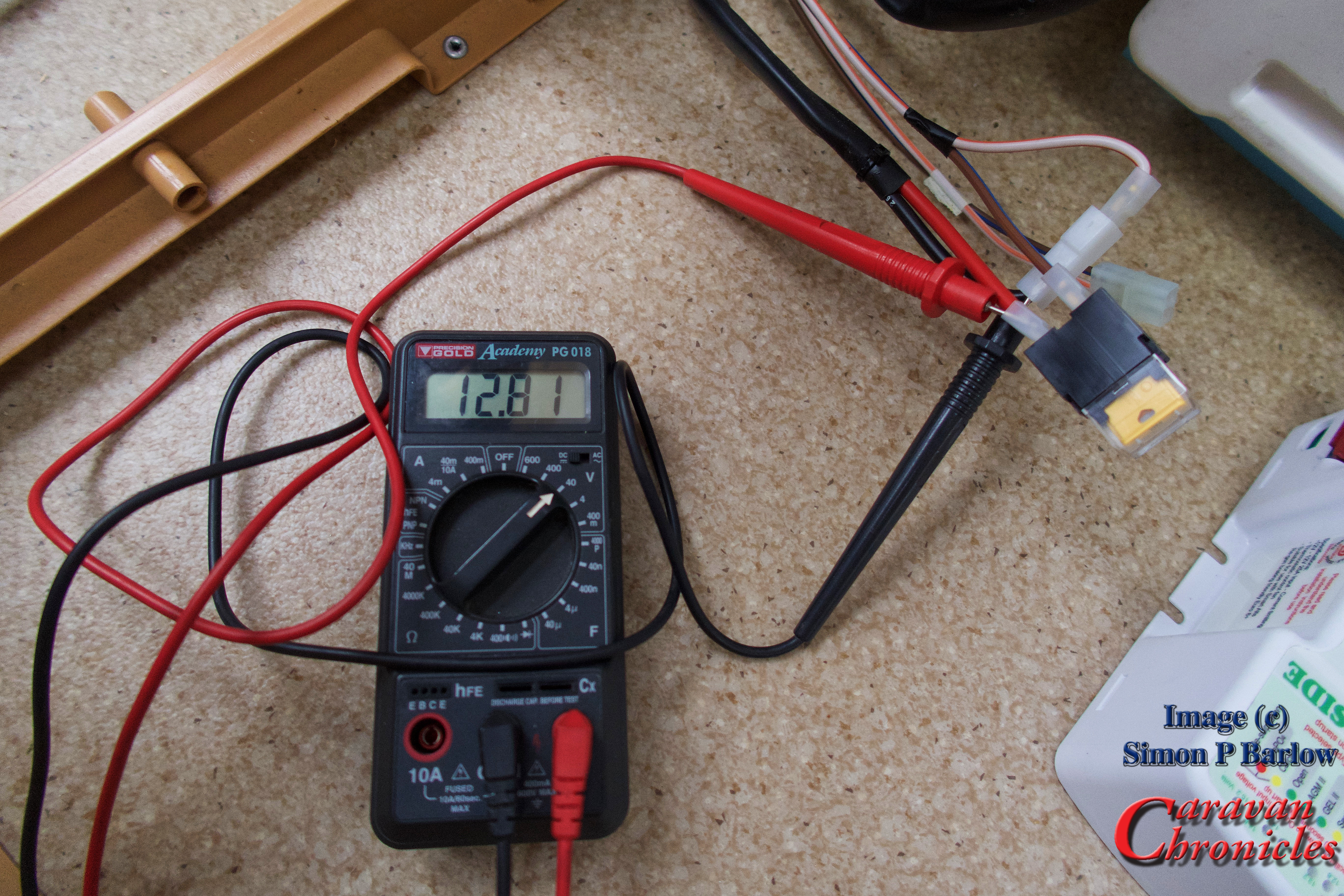

Before starting, I did a quick voltage check on the leisure battery…. 12.81 volts, which isn’t too shabby as we don’t have a solar panel and it had been February 25th when I left the Caravan show at the NEC and the battery was last charged up. Which was about 13 weeks earlier.

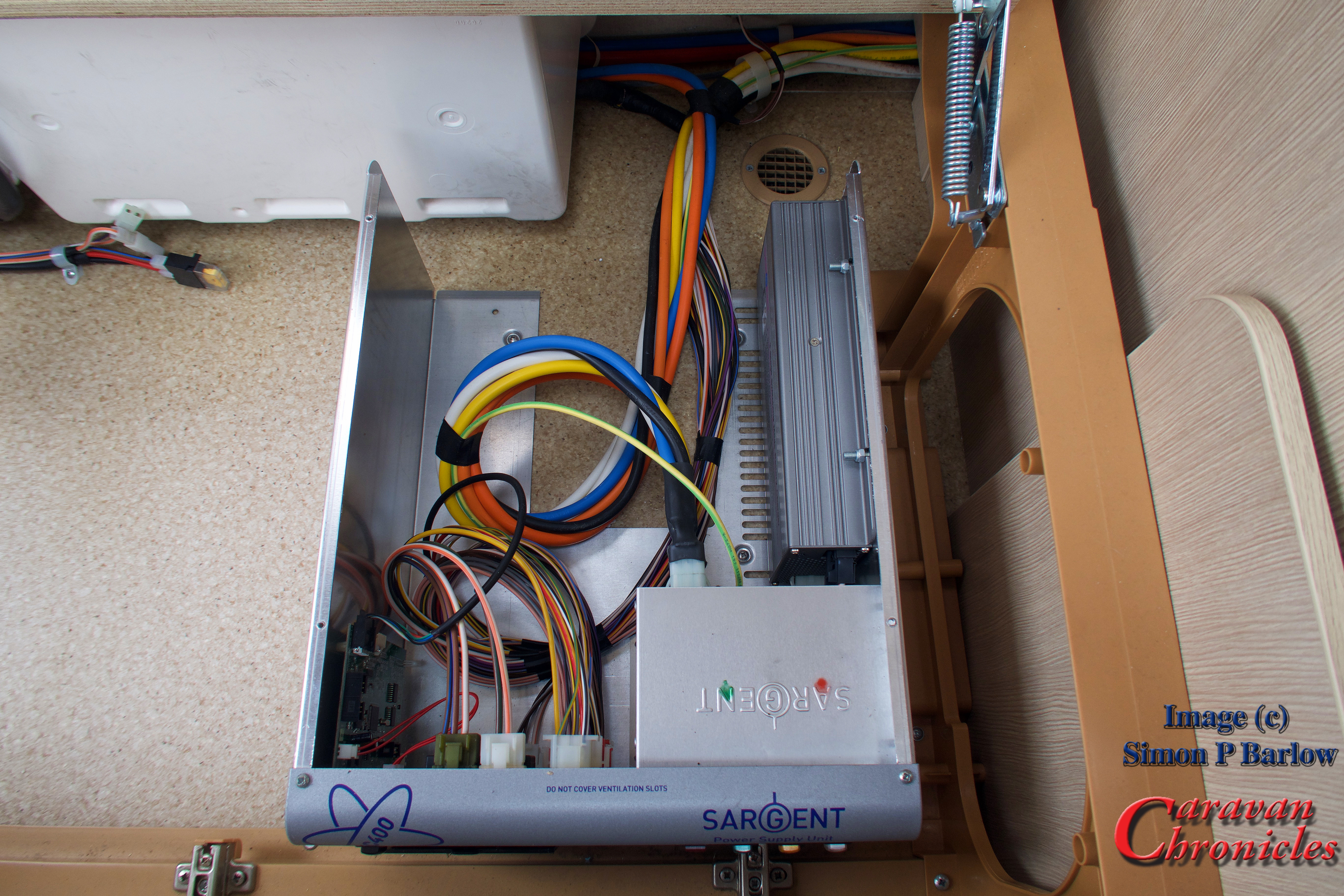

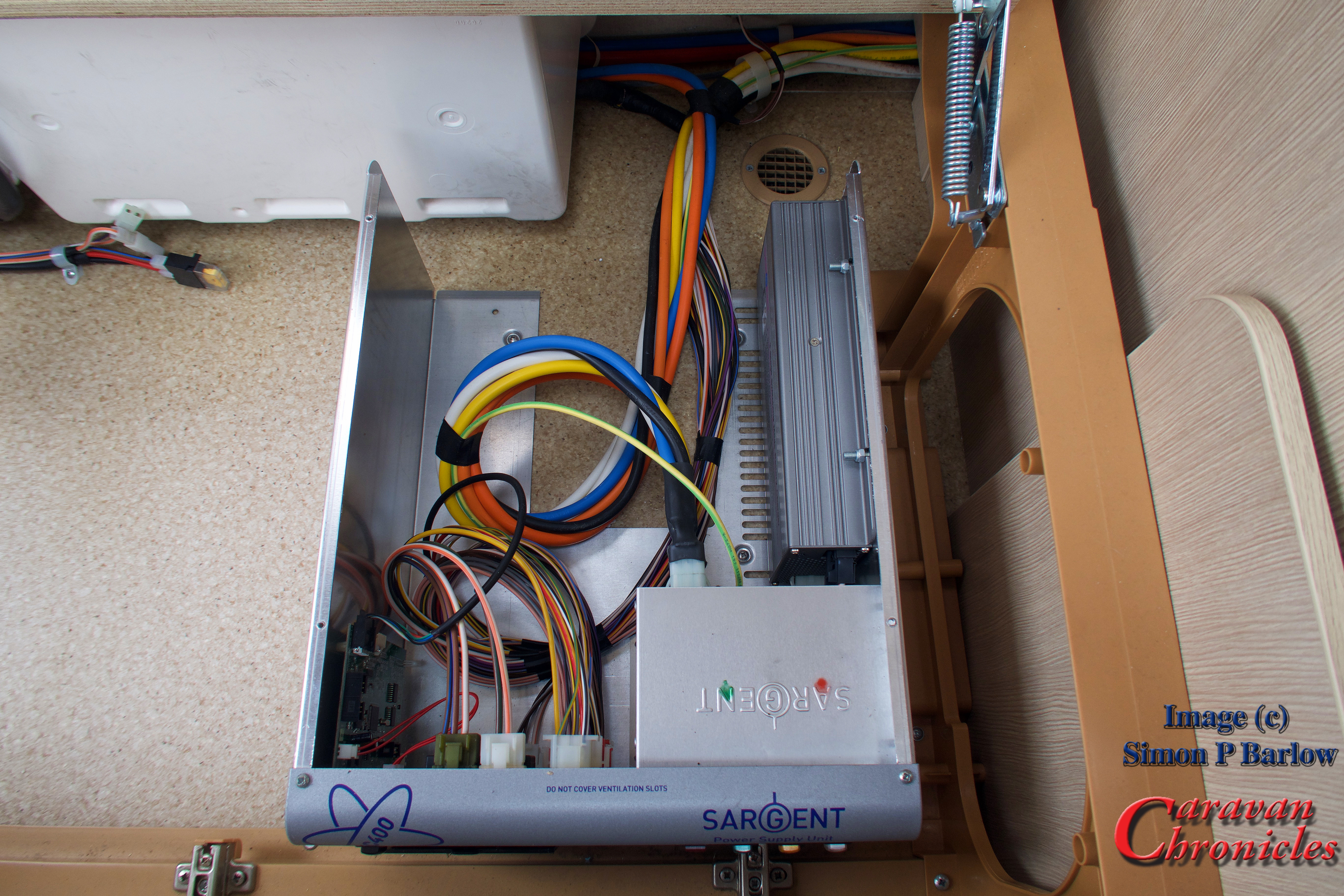

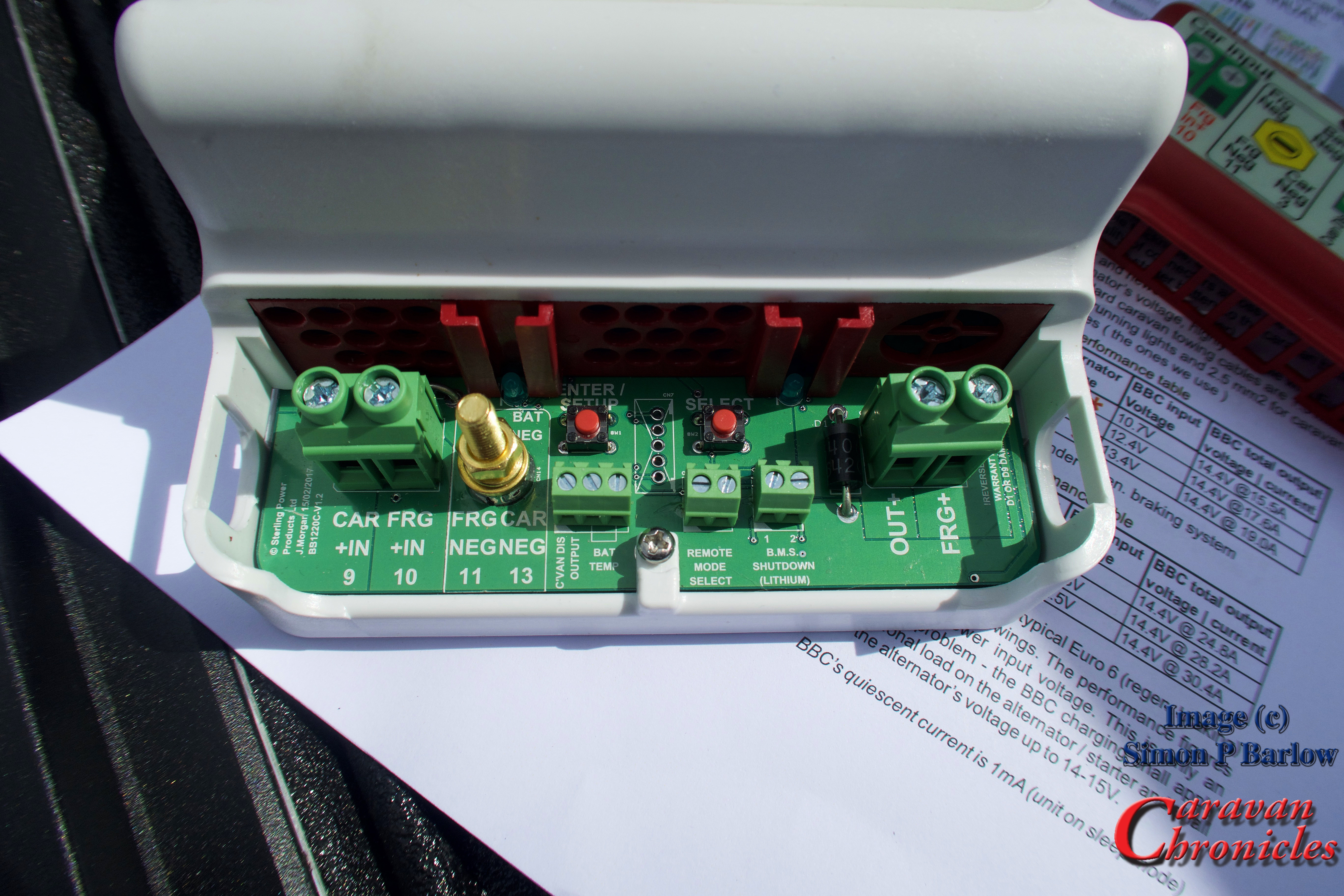

To gain access to the wiring going into the Sargent unit, I removed the 4 screws holding the top cover on and the lid simply lifted off revealing all the connections and as a bonus, service loops in the cable. This meant it should be possible to install the wild side unit without having to do any cable splicing. I did debate at this stage if it would be possible to install the Wildside unit inside the Sargent box… but I decided as I didn’t know the heat gain of the Wildside unit, it might be prudent not to attempt it.

The cables inside the Sargent box are basically separated into two looms. One 12 volt and the other 230 volt which keeps things easy and neat. Also the back of the circuit board within the Sargent unit was printed with each of the plug numbers, so doing all the planning paid off as I could simply find the plug number from my diagram and locate the correct cable easily.

I decided I was going to do a pre-install and connect the Wildside unit up and do a few tests, then once I was happy I’d go ahead and do a full more permanent installation.

It was simply now a matter of finding the plug I needed, unplugging it, locating the correct wire, cutting it and terminating it in the Wildside unit.

I cut the cables about 4 inches away from the circuit board plug. This would give me plenty of length to crimp on a sleeve connector and heat shrink if I needed to remove the Wildside unit. As a backup I have also ordered some replacement pin inserts for the plugs so I could always re-terminate directly into the plug.

The next connections would be the incoming feed from the vehicle. 4 cables, two neutral and one positive fridge supply from pin 10 and one positive charging supply from pin 9. These arrive from the 13 pin plug via the fuse box mounted on the front wall through two 20 amp fuses and to the Sergeant unit. I had trouble identifying the cables as the colours were not as indicated in the manufacturers drawings. So to double check I removed the fuse box to gain access to the 13 core cable where it terminates.

It was easy enough now to trace the correct cables and confirm with my multimeter. So all the connections now made, albeit temporary, I could install the 20 Amp main battery fuse and make sure the Wildside unit powered up OK.

Don’t worry about the brass bolt holding together the three cables, it was so I could easily get a clamp meter on the cables to take current readings.

It started up without any problems and so I could connect up the 13 pin plug to the Amarok and start the engine and take a few measurements.

I checked the vehicles voltage and it was sat at 14.5 with run/stop disabled and the engine ticking over. OK how come I had a voltage of 14.5 volts in the vehicle with a Euro 6 engine ticking over? Well the Wildside unit basically makes the vehicle’s ECU think that the vehicle battery requires charging (remember an Euro 6 engine cranking battery will only ever be charged to 80% of its capacity so that regen will always work).

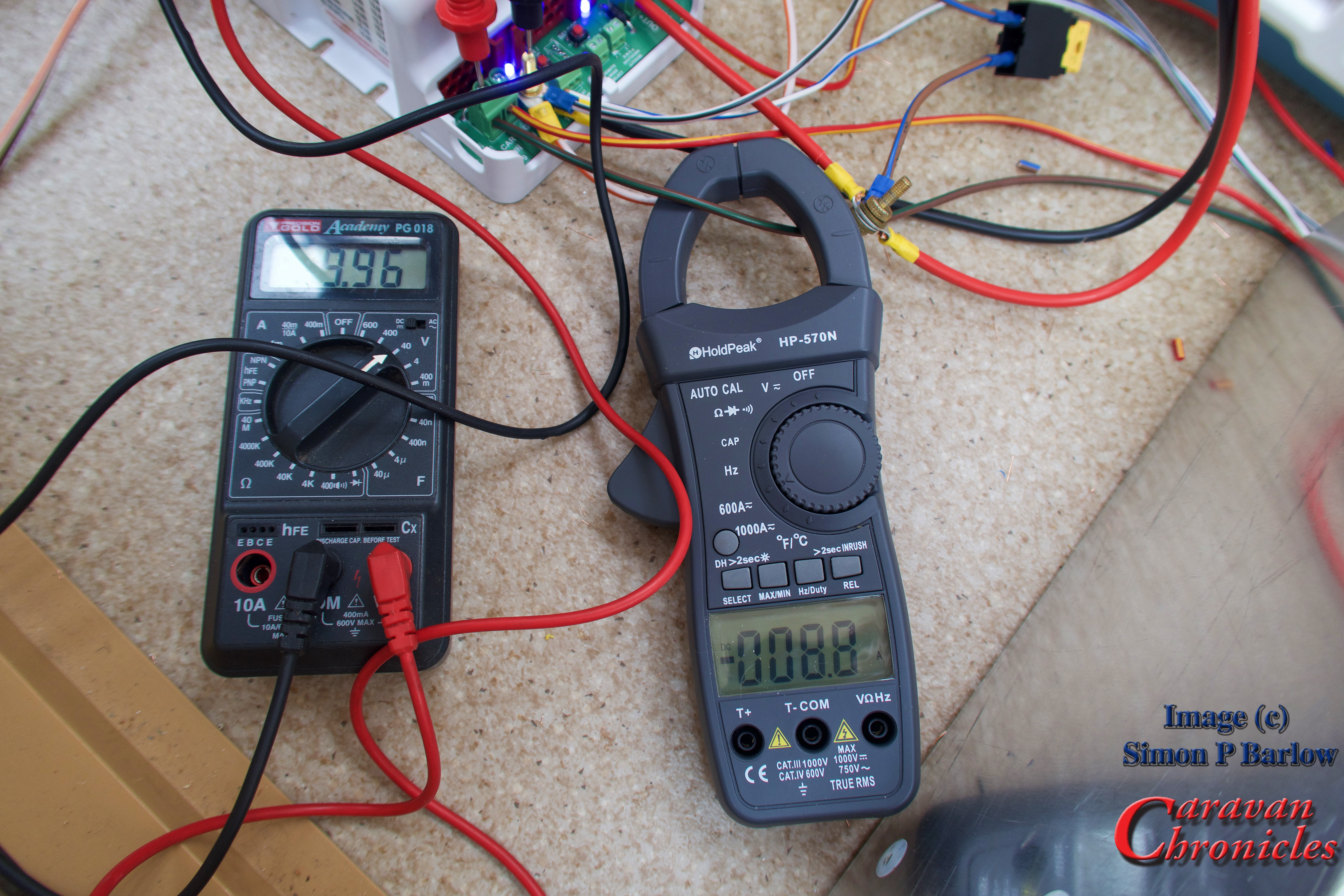

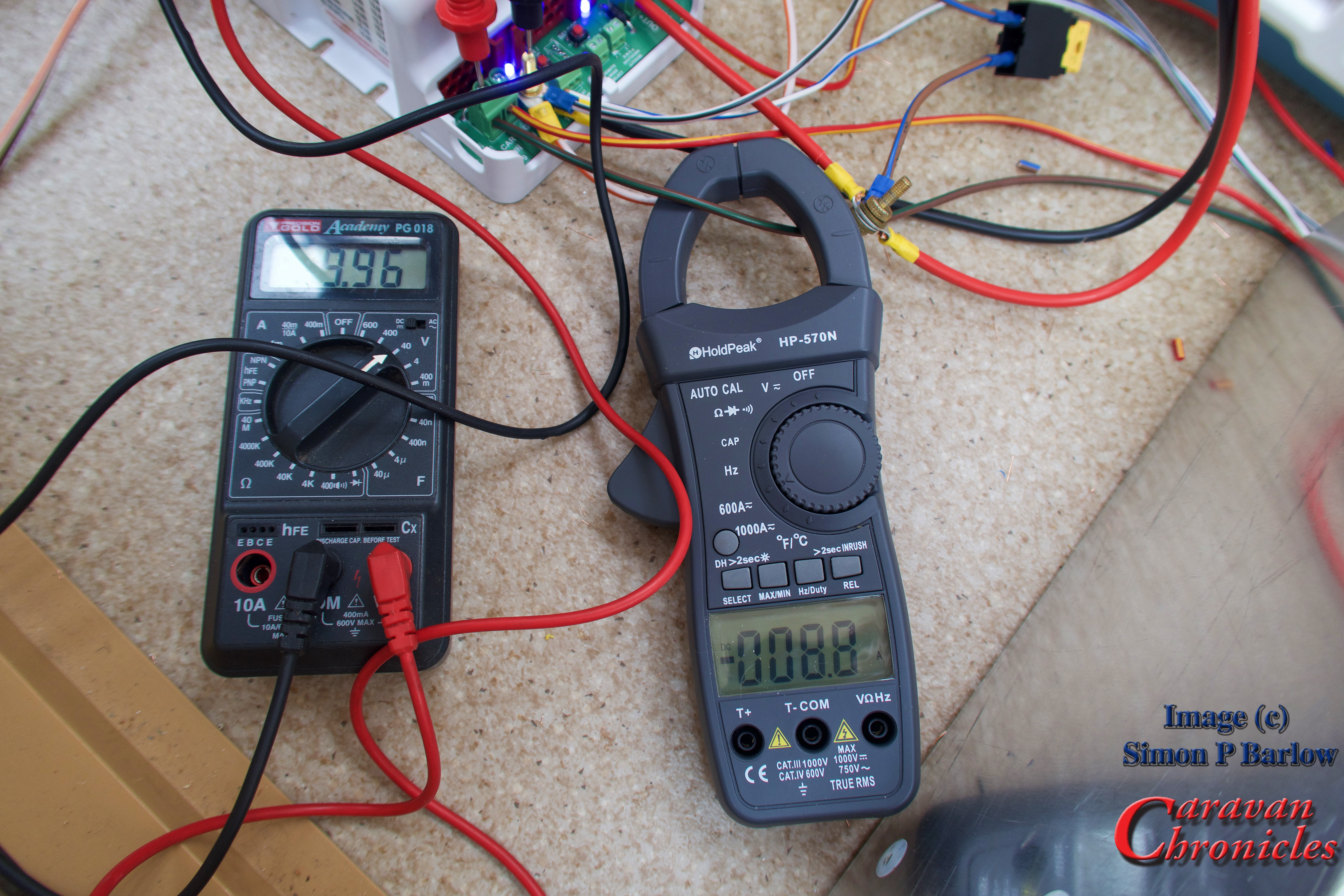

The first reading I checked was the leisure battery incoming link. I had a reading of 9.96 volts and a current of 8.8 amps. That was quite a big voltage drop.

I moved on to test the incoming fridge circuit. This was showing 9.99 volts and a current of 13.3 amps. I had a big voltage drop somewhere. I checked the voltage at the point the 13 core cable terminates and got a reading of 12.75 volts. somewhere between the incoming cable and the termination on the Wildside unit I was getting a big voltage drop.

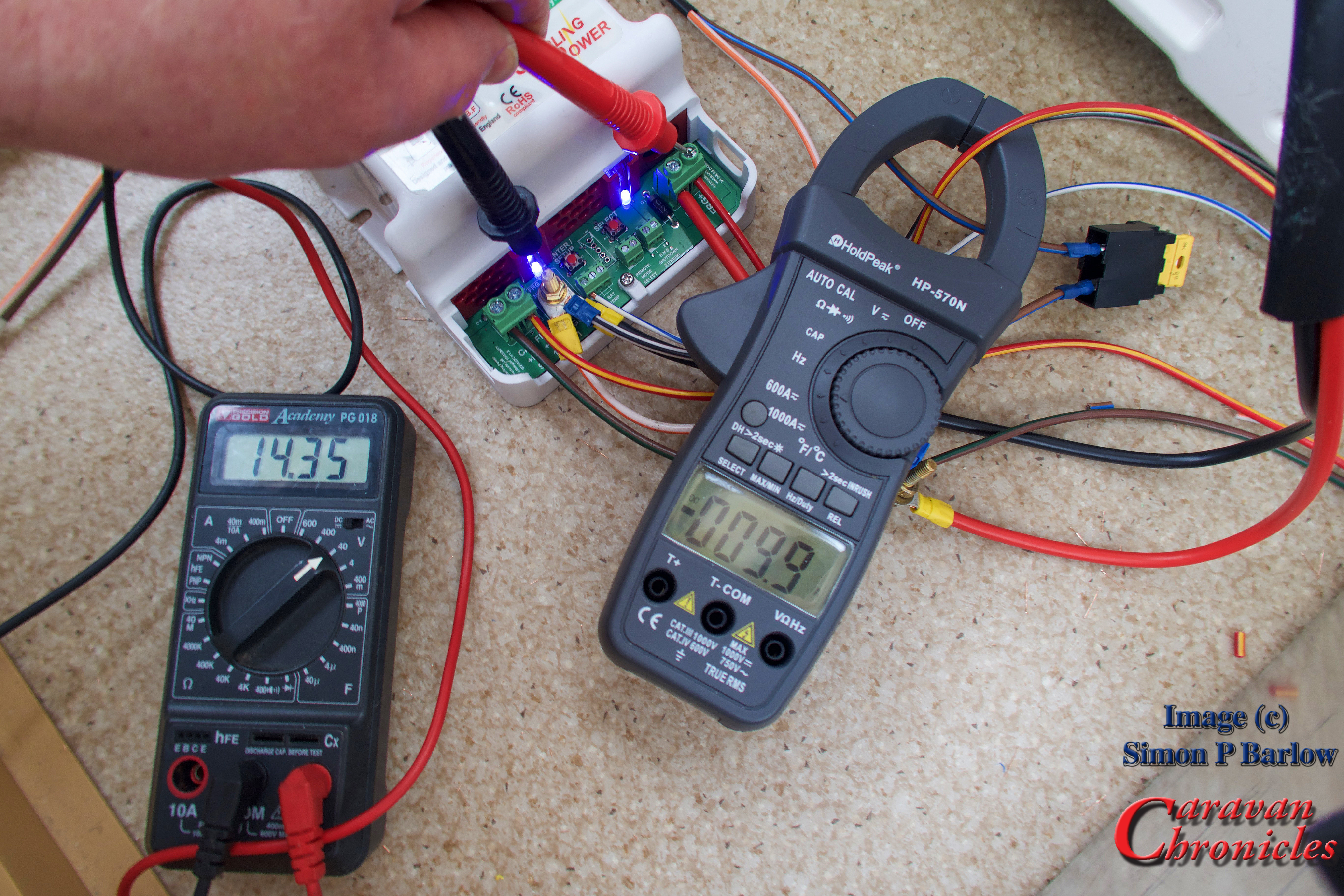

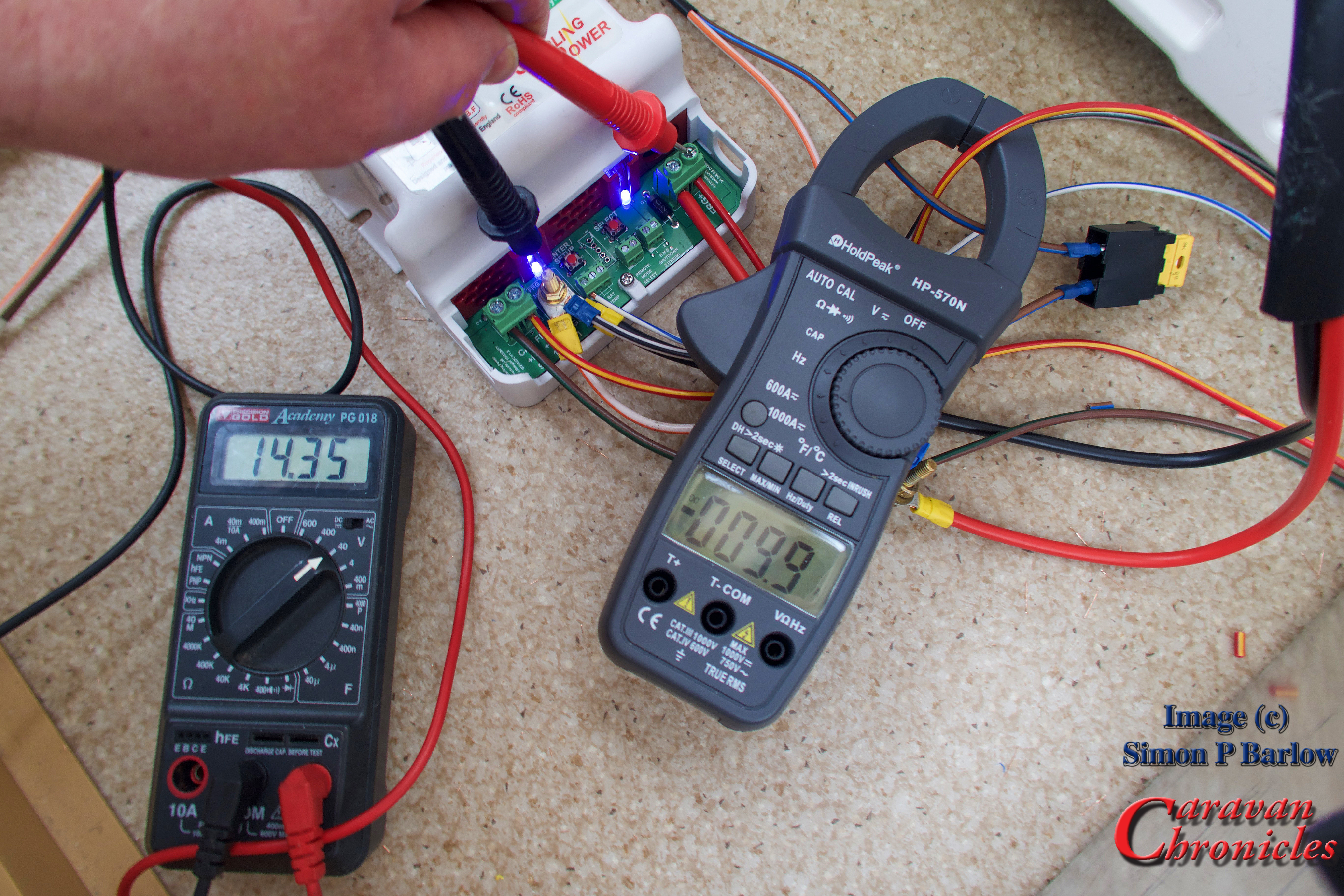

Continuing with taking some readings, I checked the fridge output and it was stable at 14.35 volts, 9.9 amps.

A problem with the fridge…

On the original caravan wiring diagram it showed the fridge heating element connected with just two wires and on the face of it this looked simple enough. However when I first connected the fridge and powered up, the fridge came up with error code 10 – no power. There was definitely a supply voltage there and it was indicating a current draw of just under 10 amps. I wondered if the voltage detect circuit was polarity sensitive so swiped the connections round and this cleared the error code. So double check the polarity of the connection if you get an error code 10 don’t assume there is a connection fault.

Thinking cap on…

I decided to stop at this point. Unless I could eliminate that volt drop between the incoming cable and the Wildside unit it was pointless taking any further readings.

The next thing to do would be to eliminate the existing wiring for the leisure battery charging circuit and fridge circuit between where the incoming cable from the 13 pin plug terminated and the Wildside unit. I decided to replace the existing caravan wiring with some 2.5mm² cable.

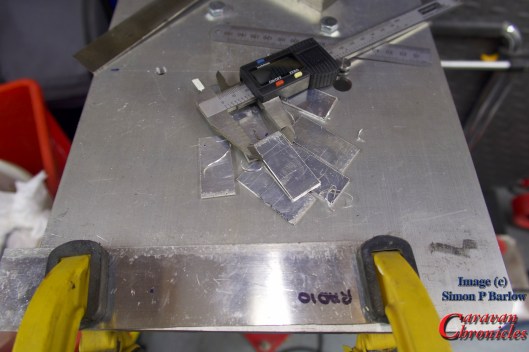

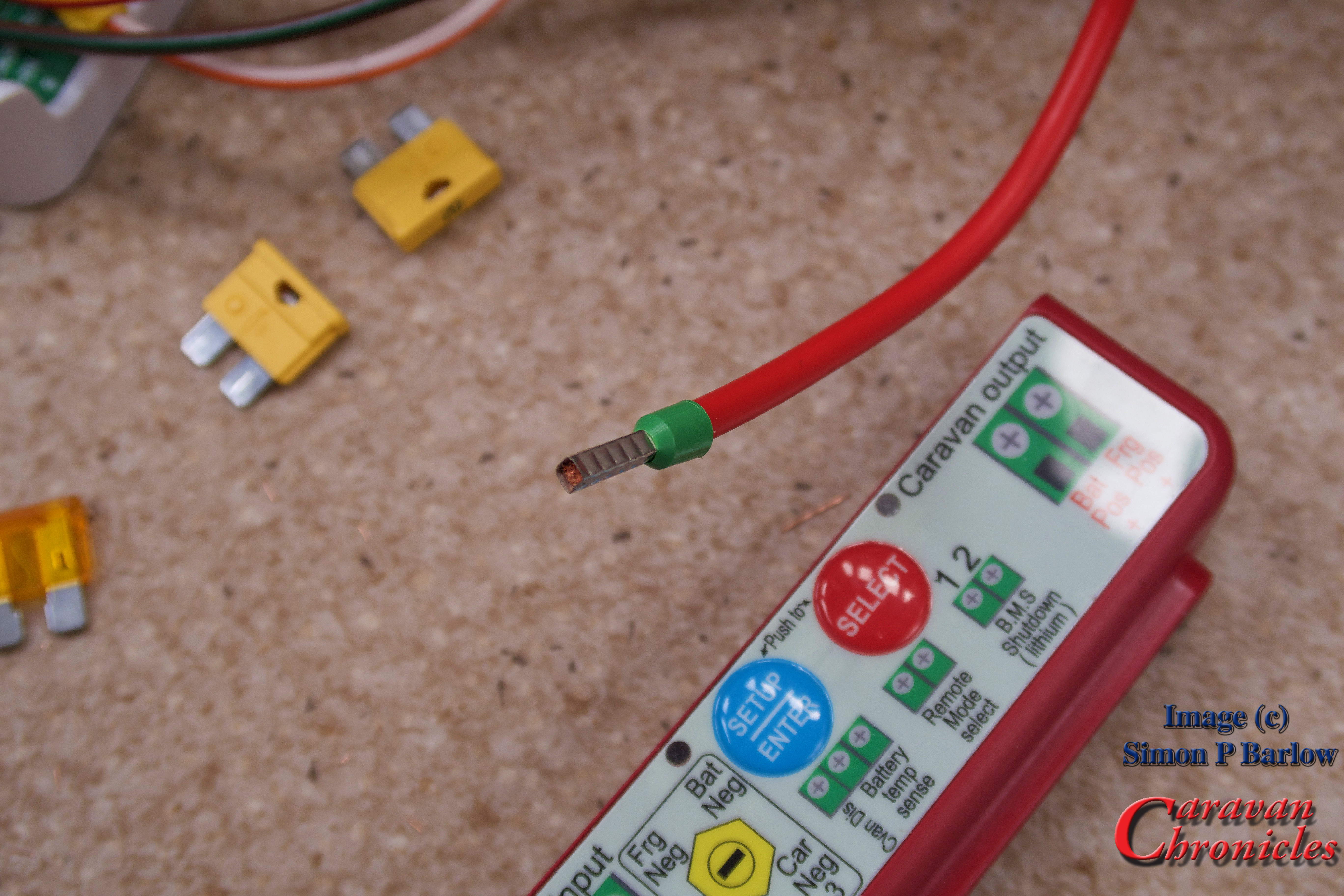

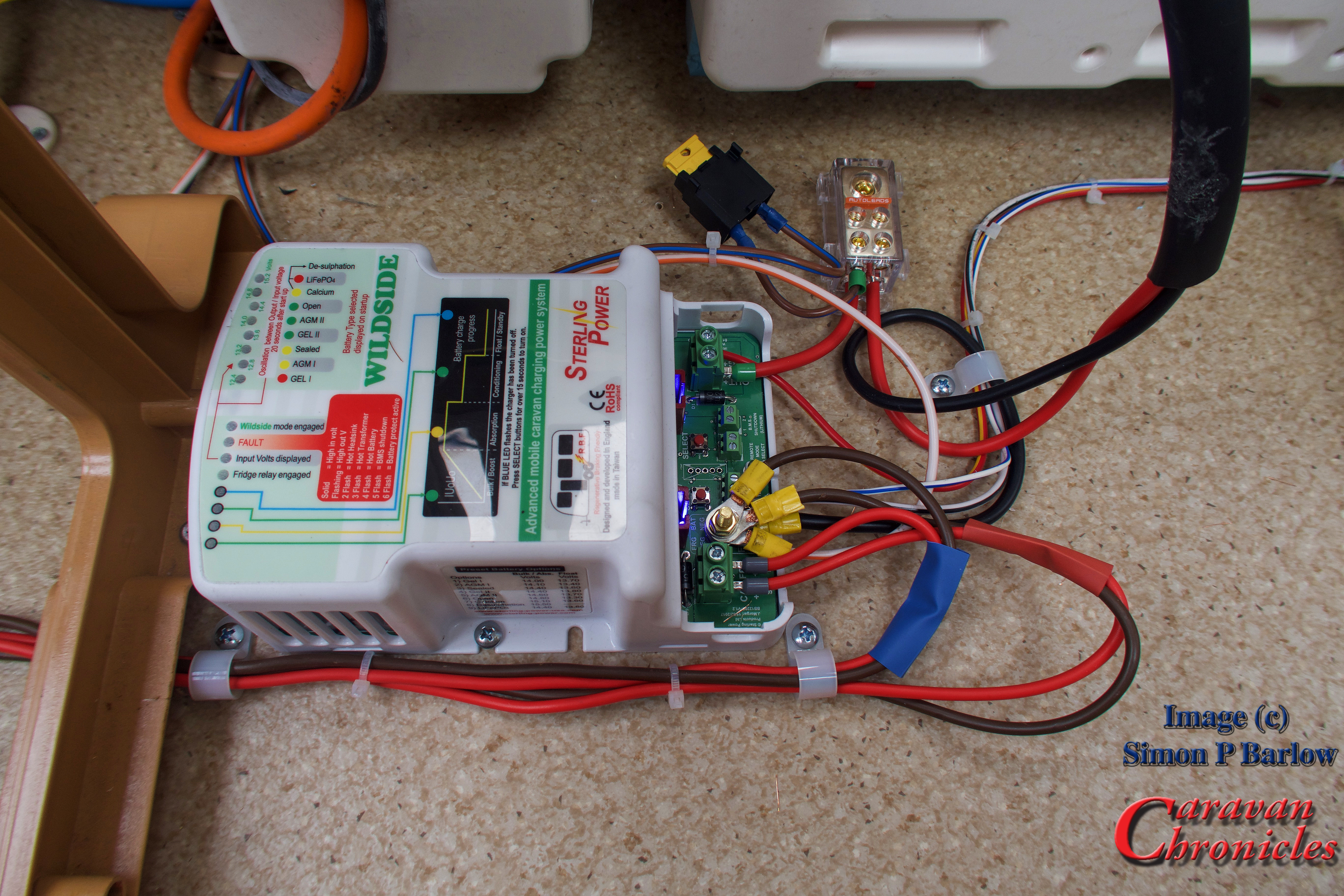

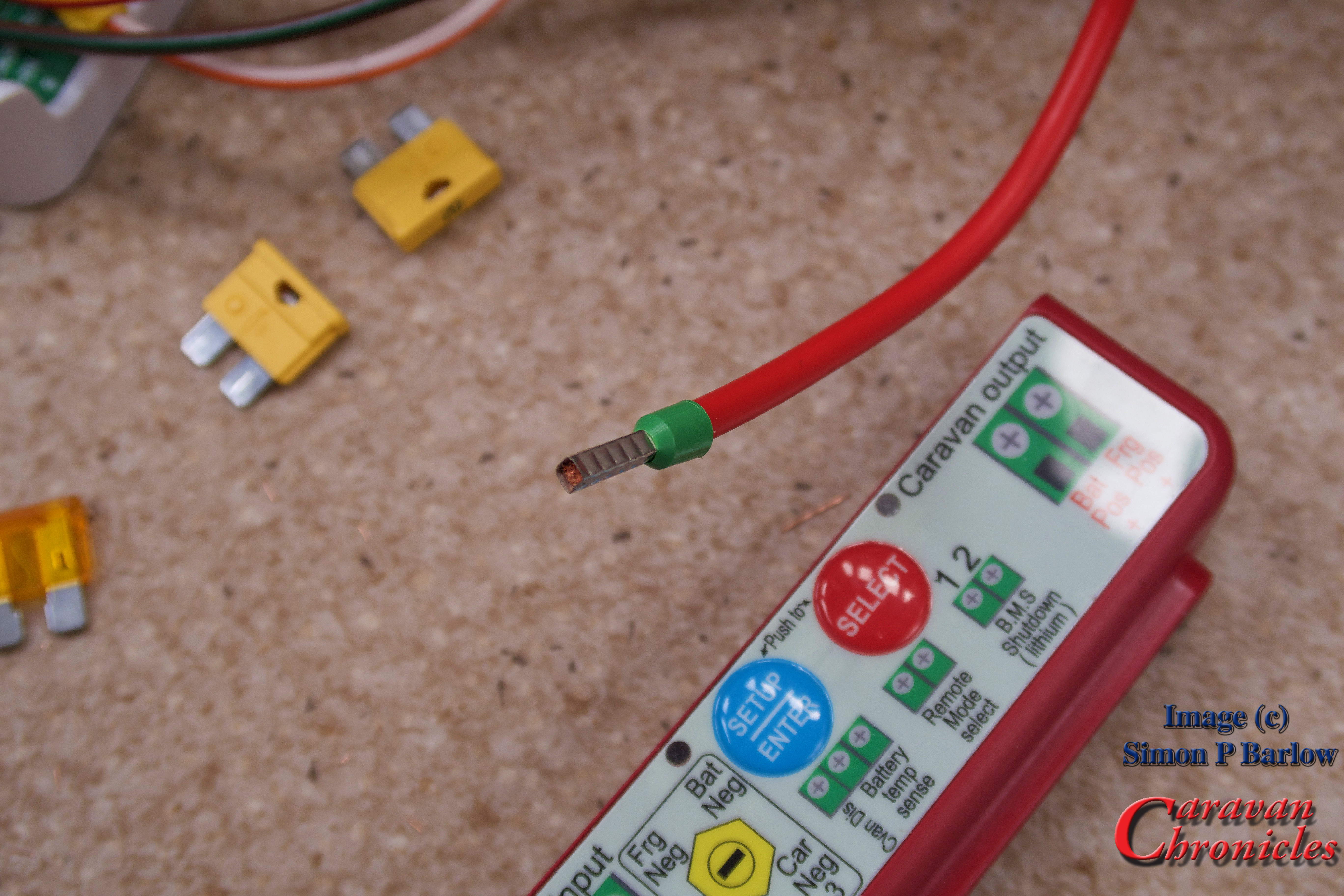

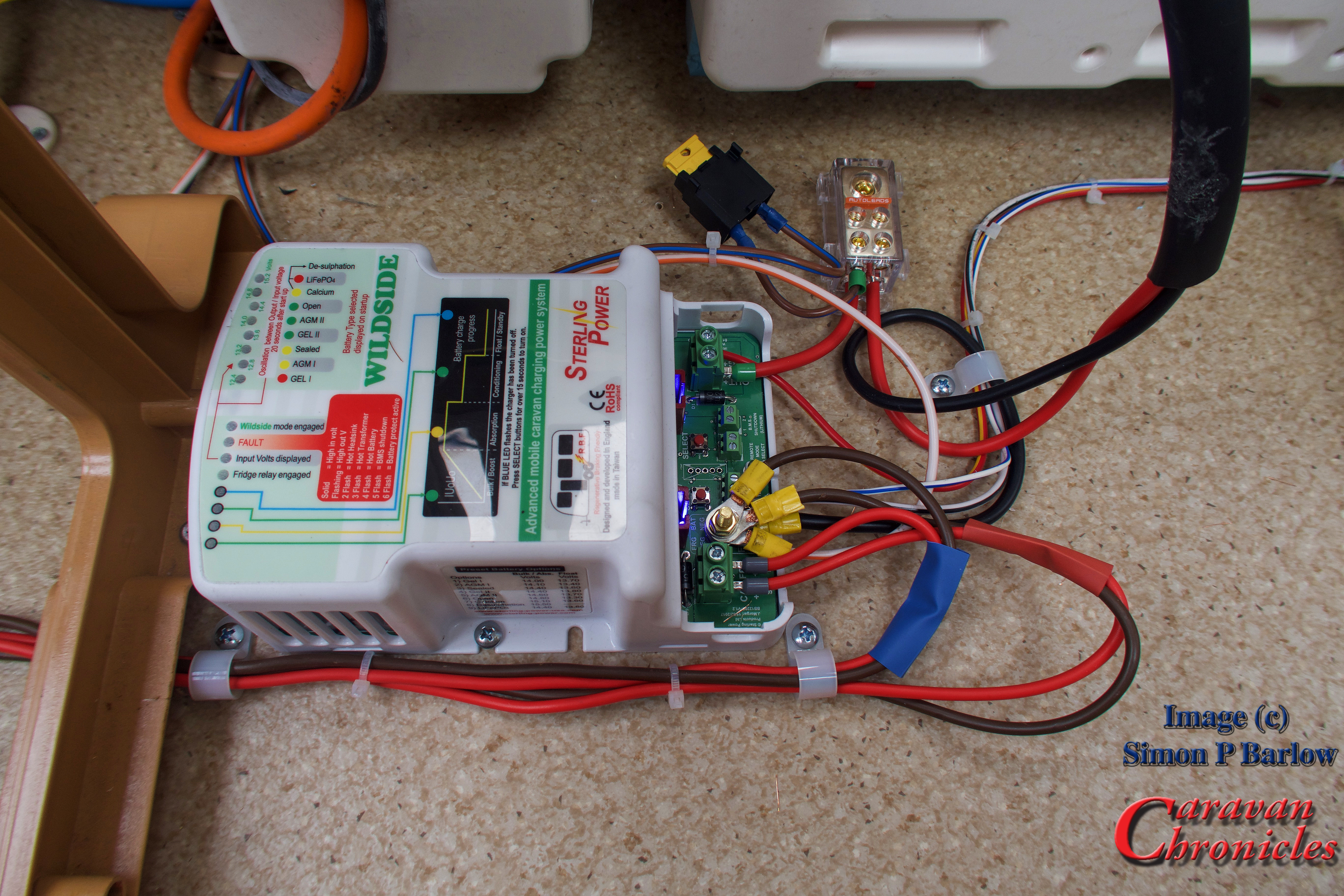

First job was to terminate all the previously terminated cables on the Wildside unit correctly with the correct size ferrule crimped on. When ever you terminate a stranded cable in a terminal block that compresses the wire, you should first crimp a ferrule on to the cable to ensure a secure connection.

Next I installed the four new 2.5mm² cables from the 13 core cable to the Wildside unit. I opted to use straight through sleeve crimp connectors to join to the cable coming from the 13 pin plug. I kept the length as short a possible – about 900mm, which resulted in not the best cable route option but I wanted to minimise voltage drop. (remember, the more current you draw through a cable and the longer the cable the bigger the voltage drop!)

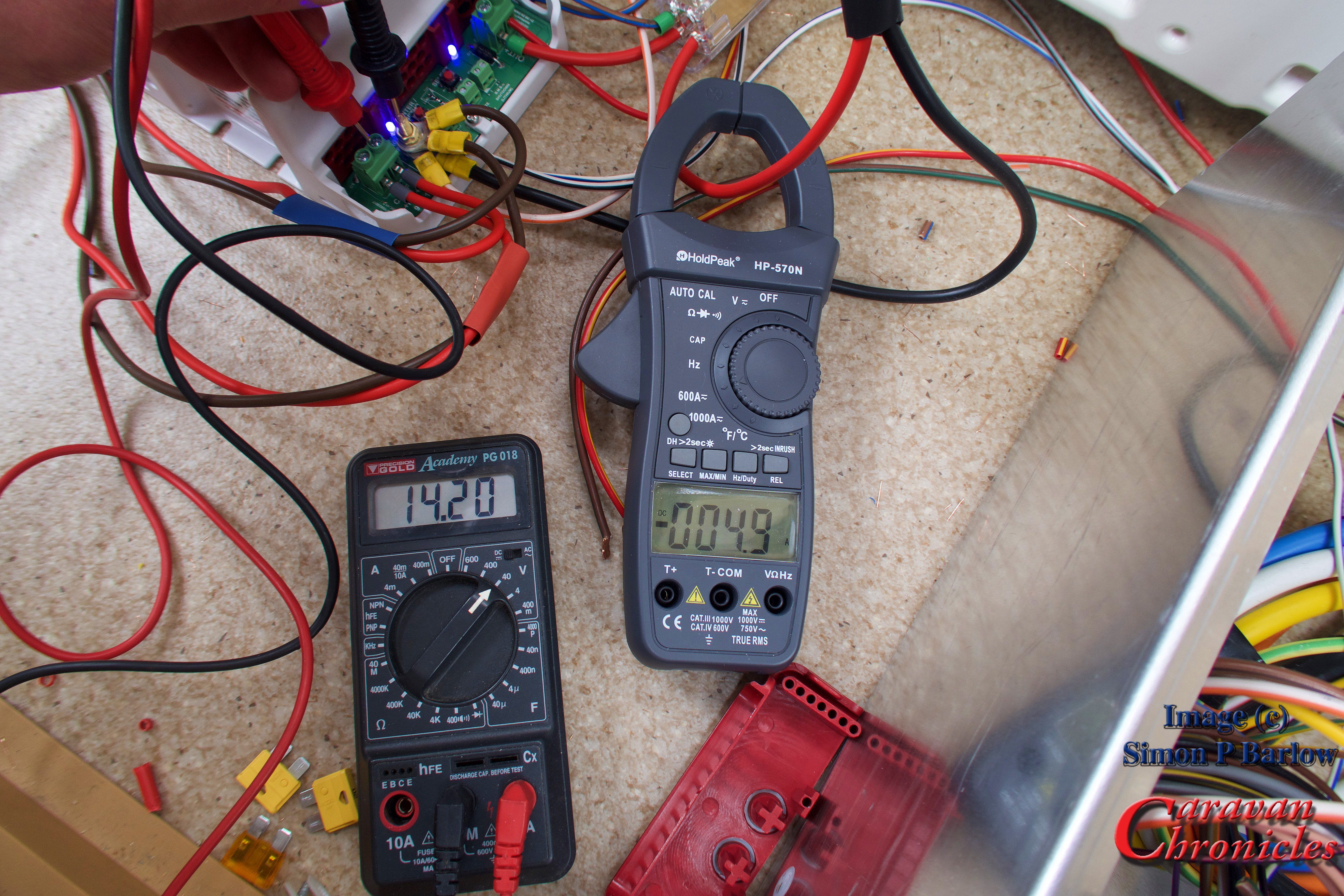

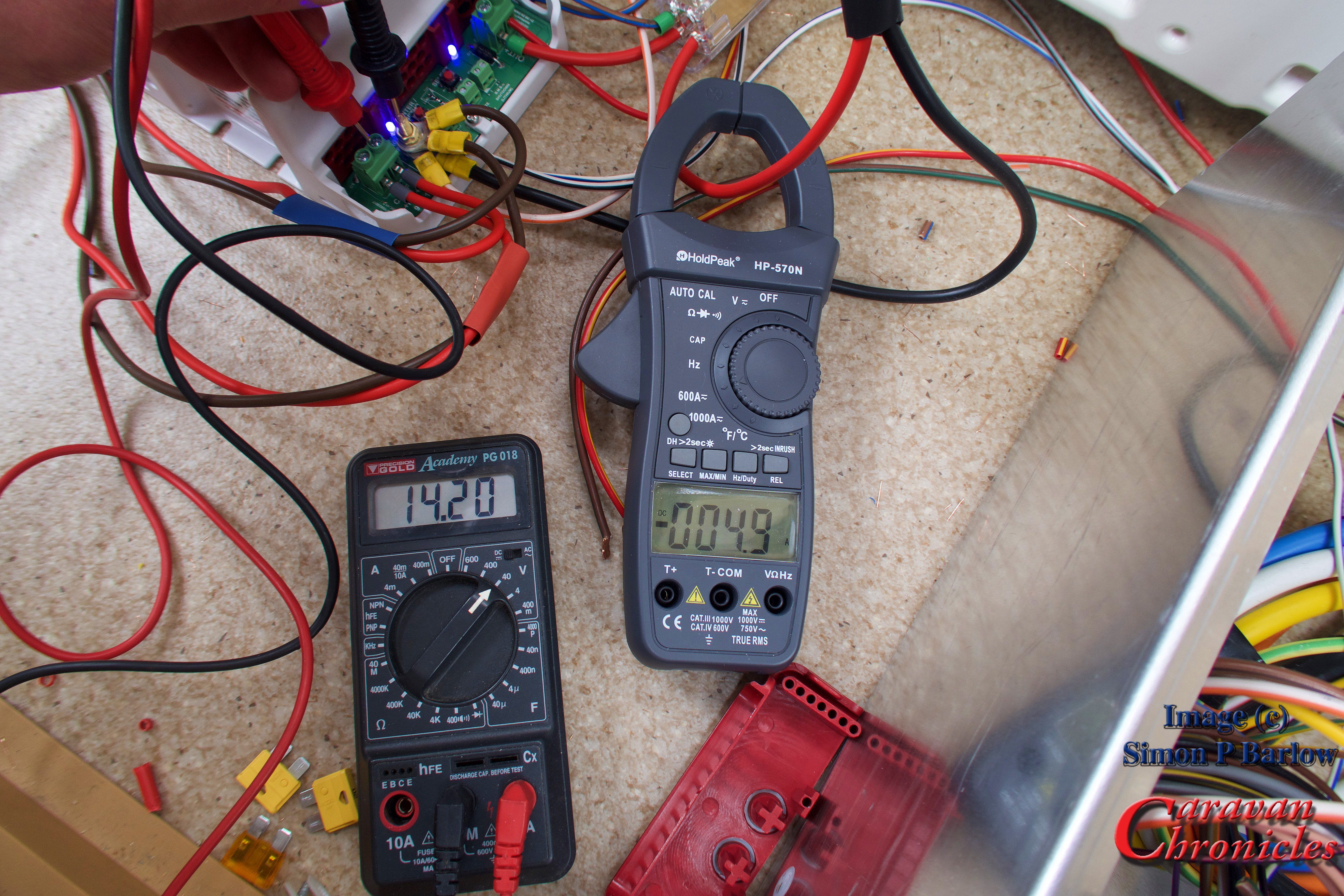

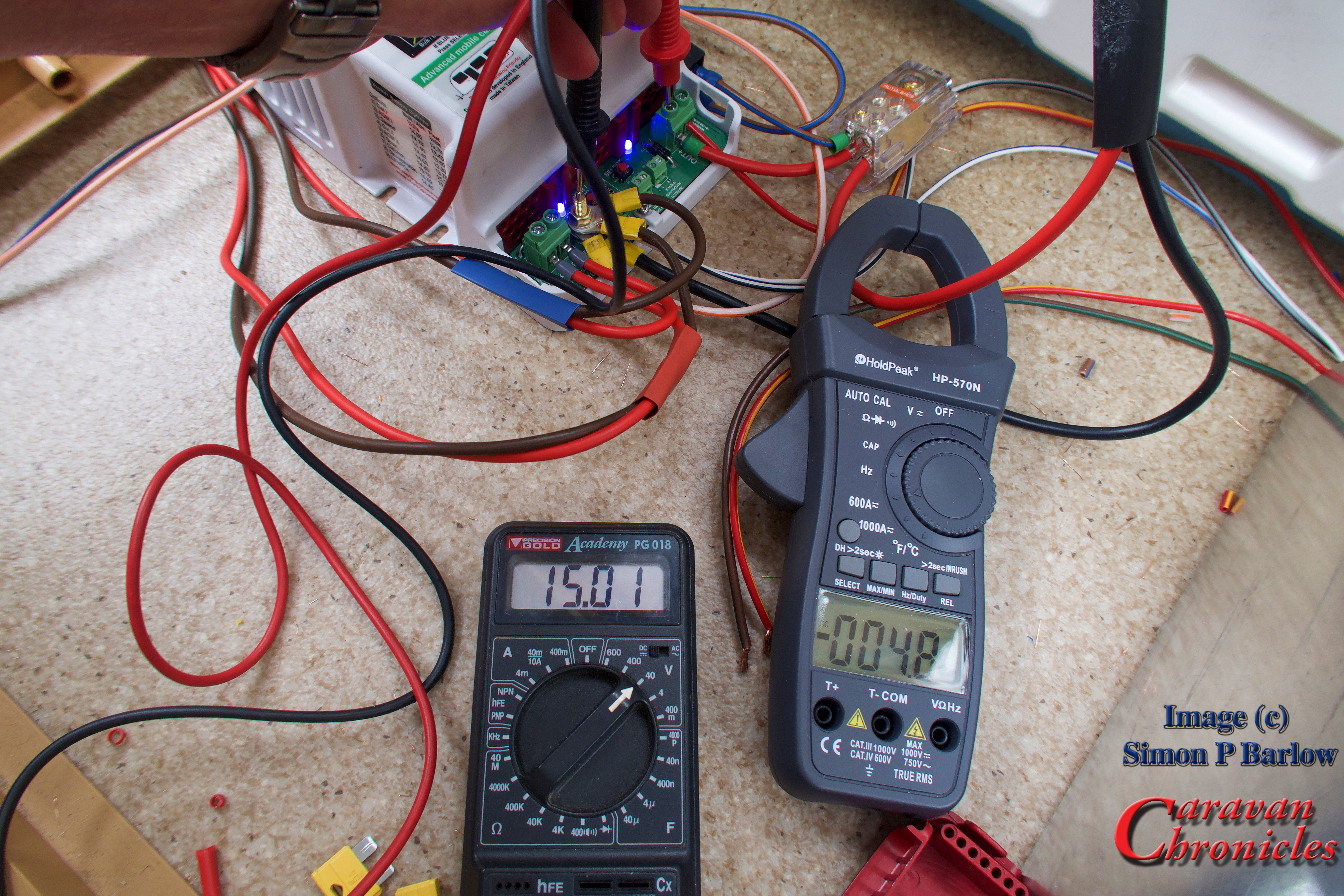

All that done, and the correct terminal block installed for the battery positive lead rather than my brass bolt, I powered up everything and hooked up the Amarok and started the engine once again. With the engine running the vehicle was showing 14.7 volts and I was now getting 14.1 volts on the incoming charing circuit with a current draw of 8.2 amps. Note: the clamp meter in the picture is actually showing the charging current for the leisure battery… 5.0 amps.

Checking the incoming fridge feed I was reading 14.2 volts and a current of 8.6 amps. Which was a vast improvement over my previous readings. (Note: the clamp meter in the picture below is still showing the battery charging current)

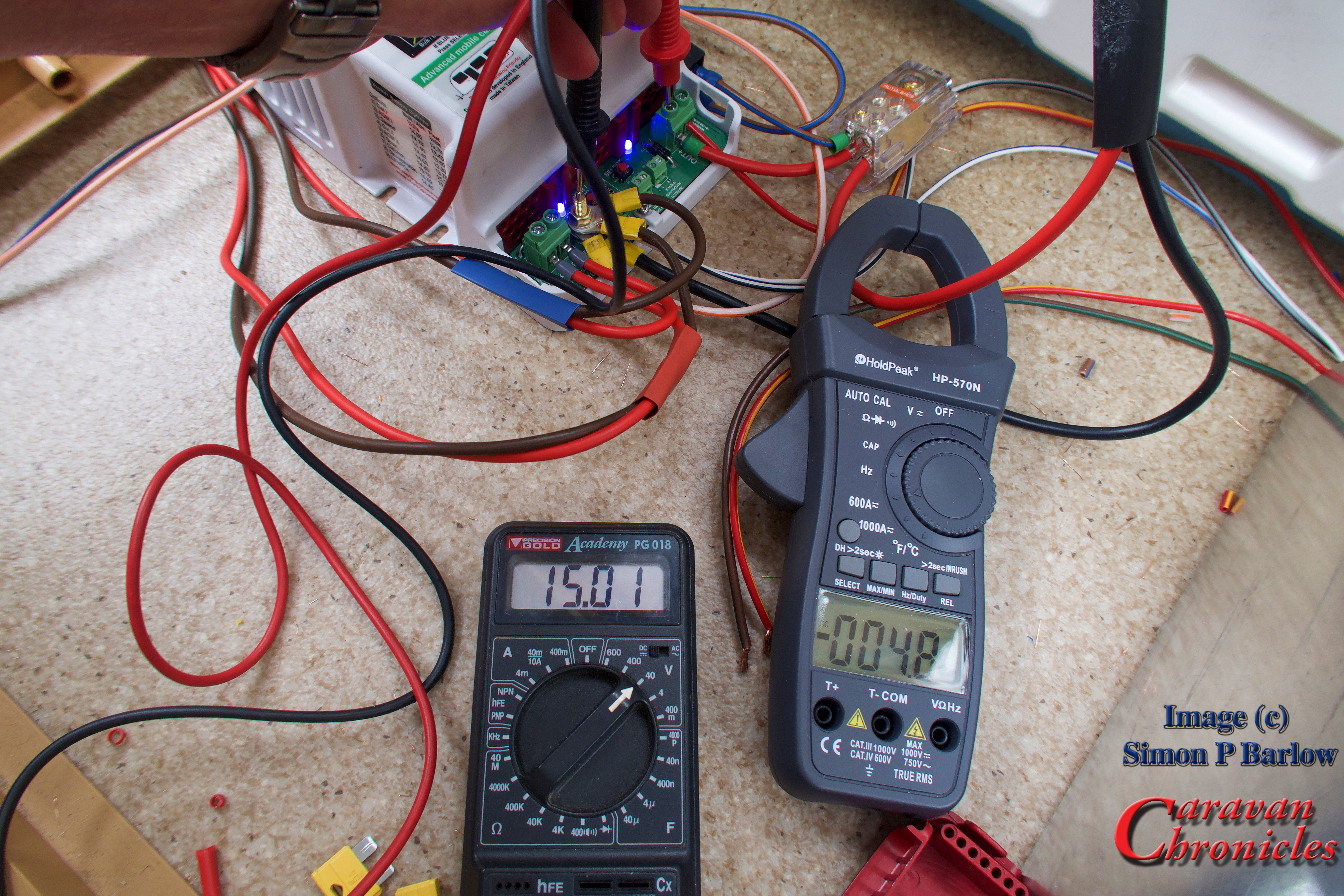

The battery charging voltage was showing 15.01 and 4.8 amps which meant I was at least charing the battery with just the engine on idle.

Doing a little maths – I was pulling 8.2 Amps via the leisure battery charging circuit and 8.6 Amps via the fridge circuit giving a total of 16.8 Amps. I was supplying 9.9 Amps to the fridge and 5.0 Amps to the battery. A total of 14.9 Amps. The difference would be due to the losses due to stepping up the voltage being supplied by the vehicle to the output voltages of the Wildside unit. In terms of watts – the vehicle was supplying 237.74 watts and the wild side units was outputting 224.49 watts.

This did make me think. As the fridge was now consuming 149.49 watts (its rated at 150 watts) so it in theory should be at it’s max efficiency… did it need to be on all the time? Could the fridge be switched on a duty cycle of say…on for 75% and off for 25%? This would then increase the ability to put more back into the leisure battery, especially useful on short runs.

Speaking to Charles Sterling, I know this unit has been rated on the conservative side and in theory 20 amps can be pulled from each circuit. This would give around 560 watts of power… and in theory about 400 watts available for charging the leisure battery. Will that damage your vehicle? Well as most Euro 6 engines are fitted with 2Kw alternators, there is still plenty of power available.

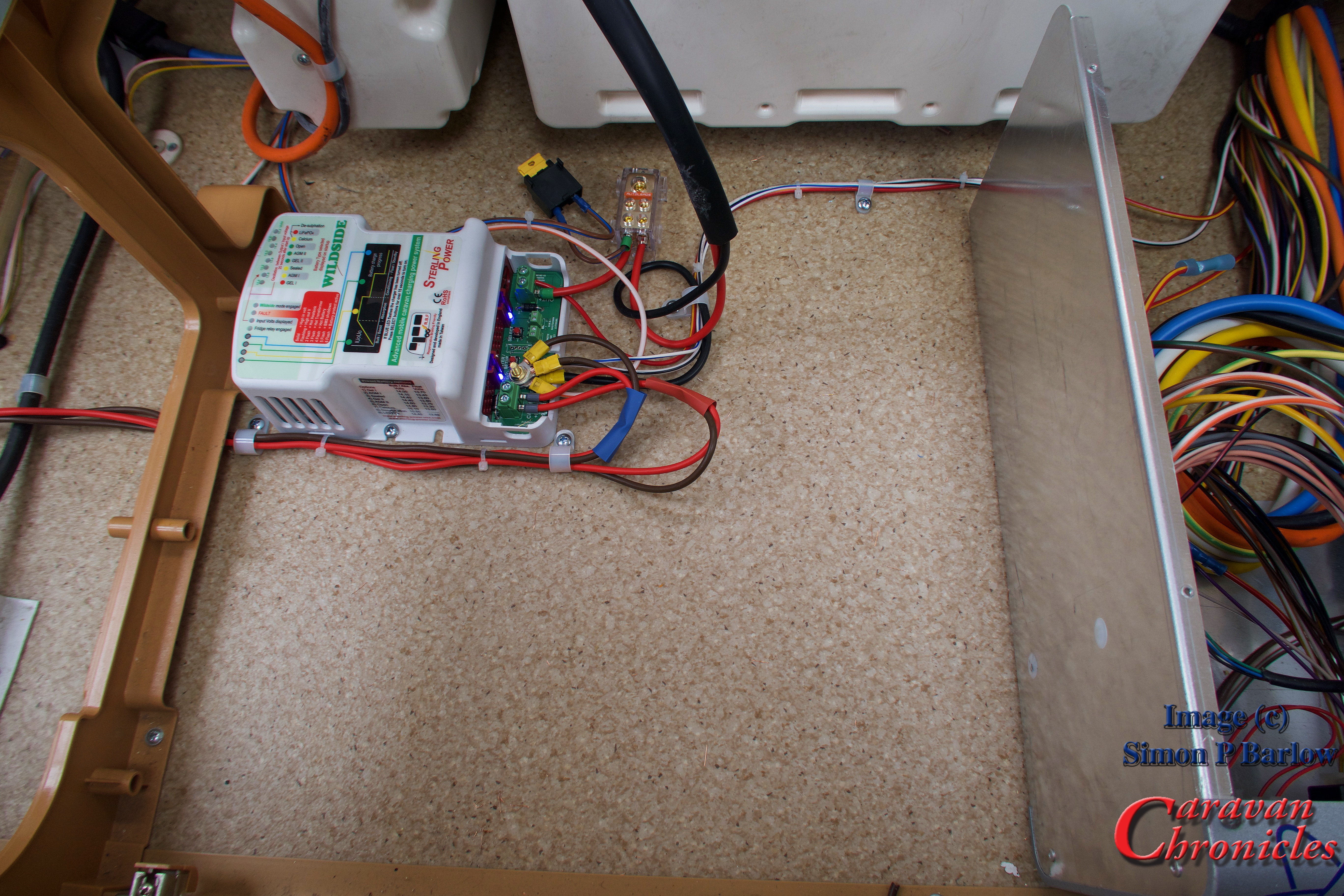

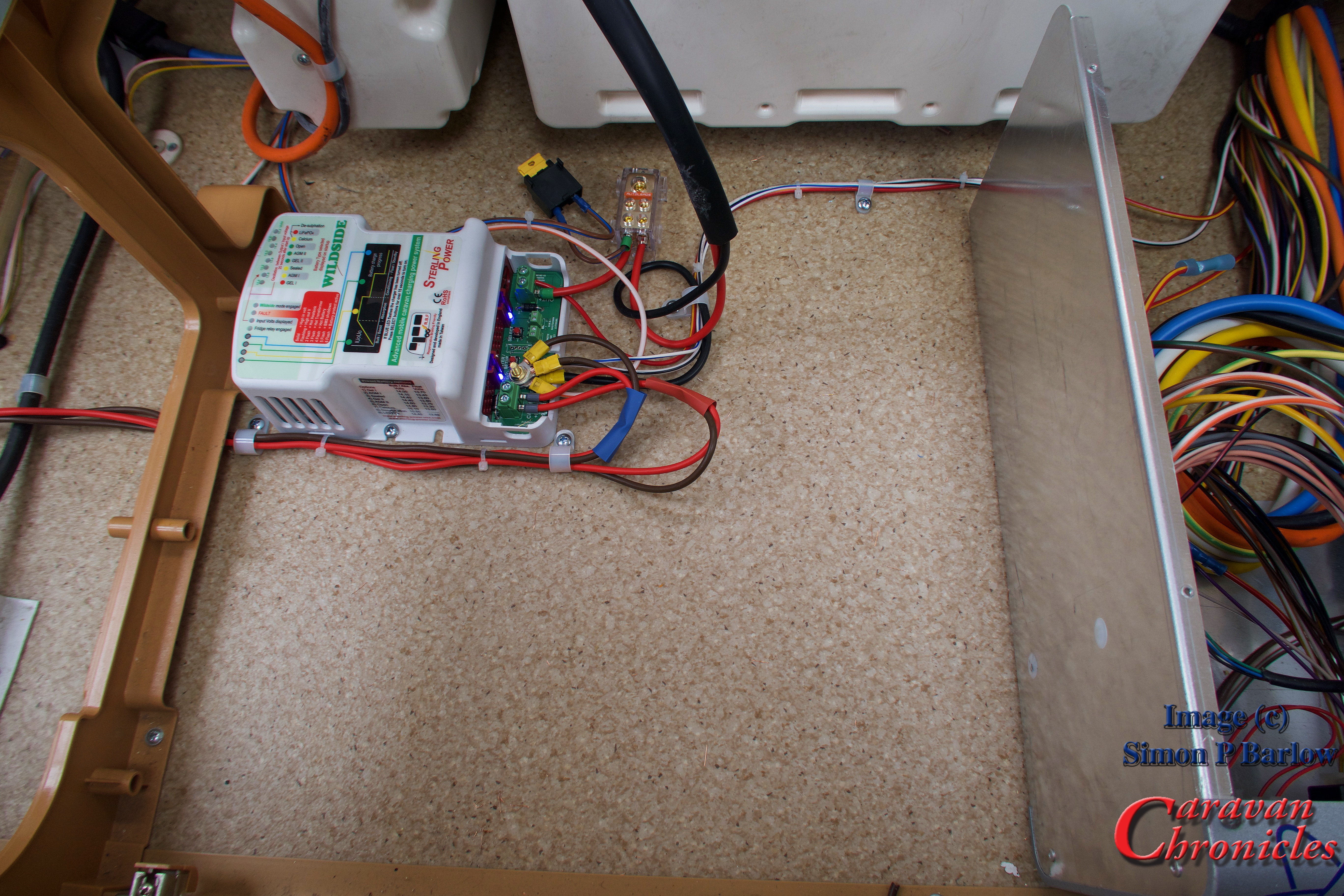

Finishing up

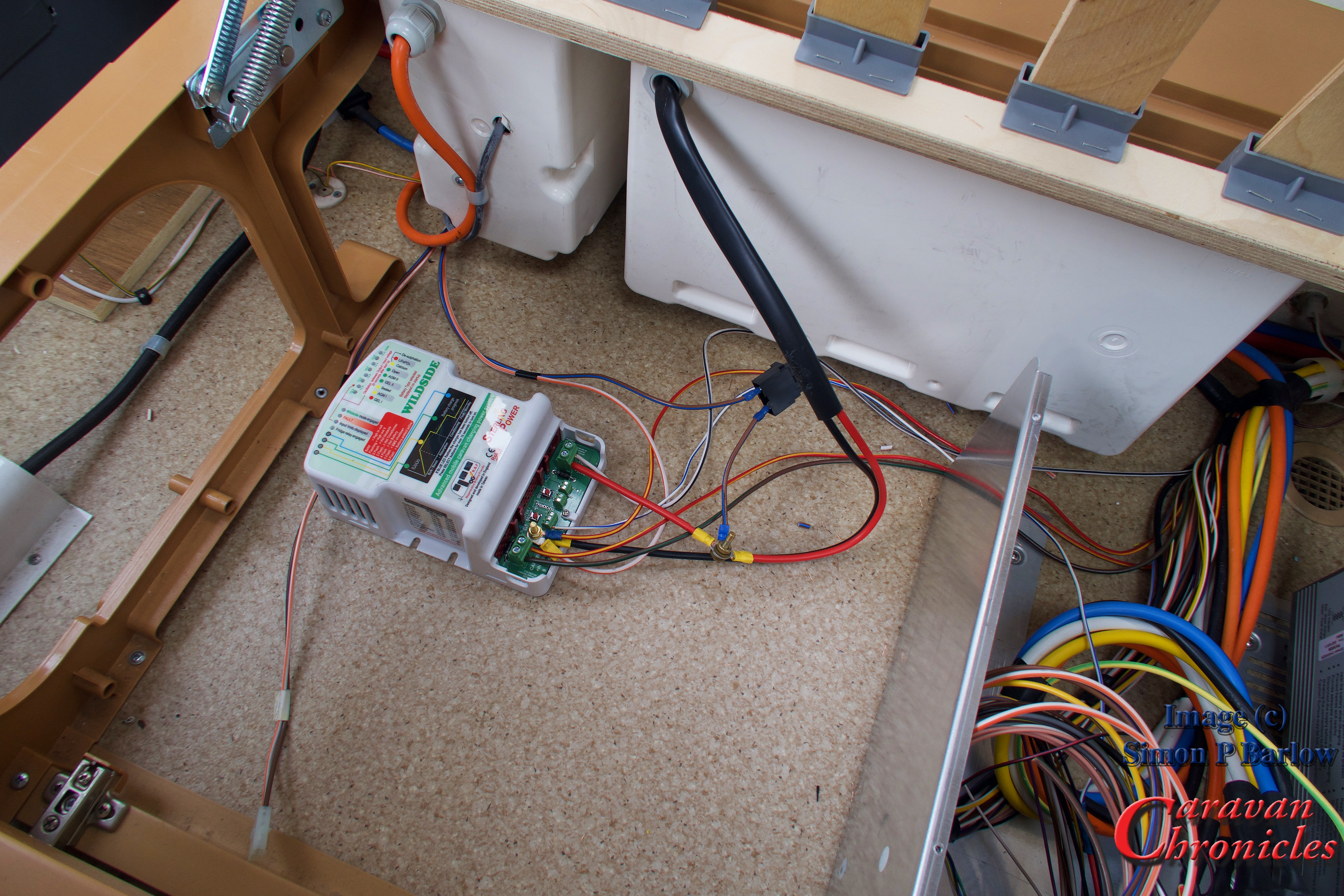

It was now a matter of tidying up my mess and installing some cable ‘p’ clips to secure everything to the floor. The two sleeves on the cables that come from the 13 core cable are there so I can identify each circuit. Red for leisure battery charging and blue for fridge circuit.

The yellow fuse you can see is the leisure battery fuse. It’s rated at 20 amps and is in circuit between the leisure battery and the caravan services, so pull that fuse and the caravan will be isolated from the 12 volt system. I’ll probably replace that with a circuit breaker in the near future.

A couple of things I thought about while doing this install.

The Sargent control box is a lot of wasted space. I recon that it should have been shrunk down to ¼ of it’s current size and probably relocated to somewhere else… maybe under the draw unit at the front of the caravan.

The incoming fuse connection panel too seemed a little flimsy. All it consisted of was a circuit board with multi plug connectors on one side and spade connection soldered on the other for the blades of the fuses to slide into. Some of the soldering looked ‘dry’ and I wondered if this was causing some of the volt drop I was experiencing… that coupled with the multi-plug connections in the loom. I know it makes the build of the caravan easier on a production line and you only need semi skilled labour to install but hey sometimes things like this matter.

Its obvious that caravan wiring is done down to a cost and the minimum standard required. I would have liked to seen some slightly heavier gauge cable for some of the connections. It amazed me that the leads that connect to the battery are 6mm² but drop down to 2.5mm² once outside the battery box and the connection between the two is just a simple male/female spade connection.

The other thing that struck me was how inefficiently the plumbing was done. I’d never really looked at it before, but casting my eye over it I think I could have laid it out a bit better and saved three push-fit connectors.

Who’s this unit designed for?

Well anyone really that has a Euro 6 engine in their tow vehicle or motorhome (if you have a motorhome you need to look at the BB1230 which is a step up again from this) and cares about maintaining their leisure battery.

If you have a motor mover fitted and use it to get your caravan out from its parking spot before you set off and then find sometimes you don’t have quite enough power to position your caravan on your pitch when you arrive or the reverse… your motor mover always seems to run out of steam trying to put your caravan back in its storage area when you return home, the Wildside unit should make sure you always have a fully charged battery and I’m my opinion is something that should be classed as an essential item.

From a lot of emails I have received it would seem that generally people with motor movers seem to be changing their batteries more frequently. A lot of the time when the motor mover stope working or works erratically the advice from the motor mover manufacturer is “you need a new battery” or” its a problem with your battery”. I”m going to throw this out there… I think it may be down to the batteries never really getting a proper charge and sulphating, radically shortening their life.

Alternatively if you do a lot of “Off Grid” (Boon-docking) camping, this will make sure you maximise the charge in your leisure battery to allow you to get the most from it. Especially if you have a Euro 6 engine.

How easy is it to install?

Planning is the key and a modicum of skill in being able to trace cables and terminate correctly. However a lot is going to depend on your caravan, how it is connected and the quality of the original installation. For me it was quite straight forward but the location of the existing components made it easy. Depending on your particular caravan you may end up having to run some additional cabling. Whatever you do, do not cheap-out on cable termination! Buy the right terminals and a good ratchet style crimp tool and make sure any cable you install is a good quality brand of the correct gauge.

Were there any issues?

Nope, it worked straight out of the box.

What next?

Road test! In a few weeks we are travelling down to Glastonbury which is between a 5 and 6 hour tow and I’ll be taking readings during the trip to see how the battery is being charged and the fridge temp. Just for the pure fun of it….. I’m going to try to make ice cubes in the freezer so we have ice for our drinks when we arrive! I’ll let you know how I get on.

Looking forward.

The biggest problem really is the fridge. A three way absorption fridge is probably the single most inefficient way of chilling anything. Whether its powered from 12 volts, 230 volts or gas. Its far more efficient to use a compressor fridge.

Now a 230 volt compressor fridge is relatively cheap when compared to a three way absorption fridge, great for when you are on hook up, but now imagine being able to run it via an inverter while you are driving or off grid from your battery. As they only run short periods and take less power to run. Coupled with the fact they don’t run continuously like an absorption fridge. It would be possible to do away with a 3 way absorption fridge completely. As we now have a sensible way of charging batteries, and given the fact the price of modern lithium battery technology is dropping all the time I don’t think technically we are far off making the transition. Its just down to the caravan manufactures…. so don’t hold your breath.

Contact:

Sterling Power

Stuff I used:

You can find links to all the crimp terminations and tools that I used in the Caravan Chronicles Shop

A couple of days ago I was excited to receive a package from Sterling Power containing one of the pre-production new “Wildside” units. The unit itself is robustly constructed and weighs in at about the same as a bag of sugar – 1Kg.

A couple of days ago I was excited to receive a package from Sterling Power containing one of the pre-production new “Wildside” units. The unit itself is robustly constructed and weighs in at about the same as a bag of sugar – 1Kg.

In Part 2…

In Part 2…

Operation is really simple. Press and hold the on button for five seconds and the unit will power up and display the status of the units own batteries.

Operation is really simple. Press and hold the on button for five seconds and the unit will power up and display the status of the units own batteries.

I have tried a few different TPMS ‘solutions’ over the past couple of years and all have plus points and minus points. As I am one of these people who likes to do walk rounds before setting off (throw back to my flying days I guess) I really didn’t want Formula 1 type information thrown at me all the time. I wanted a simple warning system and a simple way to check the pressure without having to remove any sensors. Fit2Go ticks these boxes.

I have tried a few different TPMS ‘solutions’ over the past couple of years and all have plus points and minus points. As I am one of these people who likes to do walk rounds before setting off (throw back to my flying days I guess) I really didn’t want Formula 1 type information thrown at me all the time. I wanted a simple warning system and a simple way to check the pressure without having to remove any sensors. Fit2Go ticks these boxes.